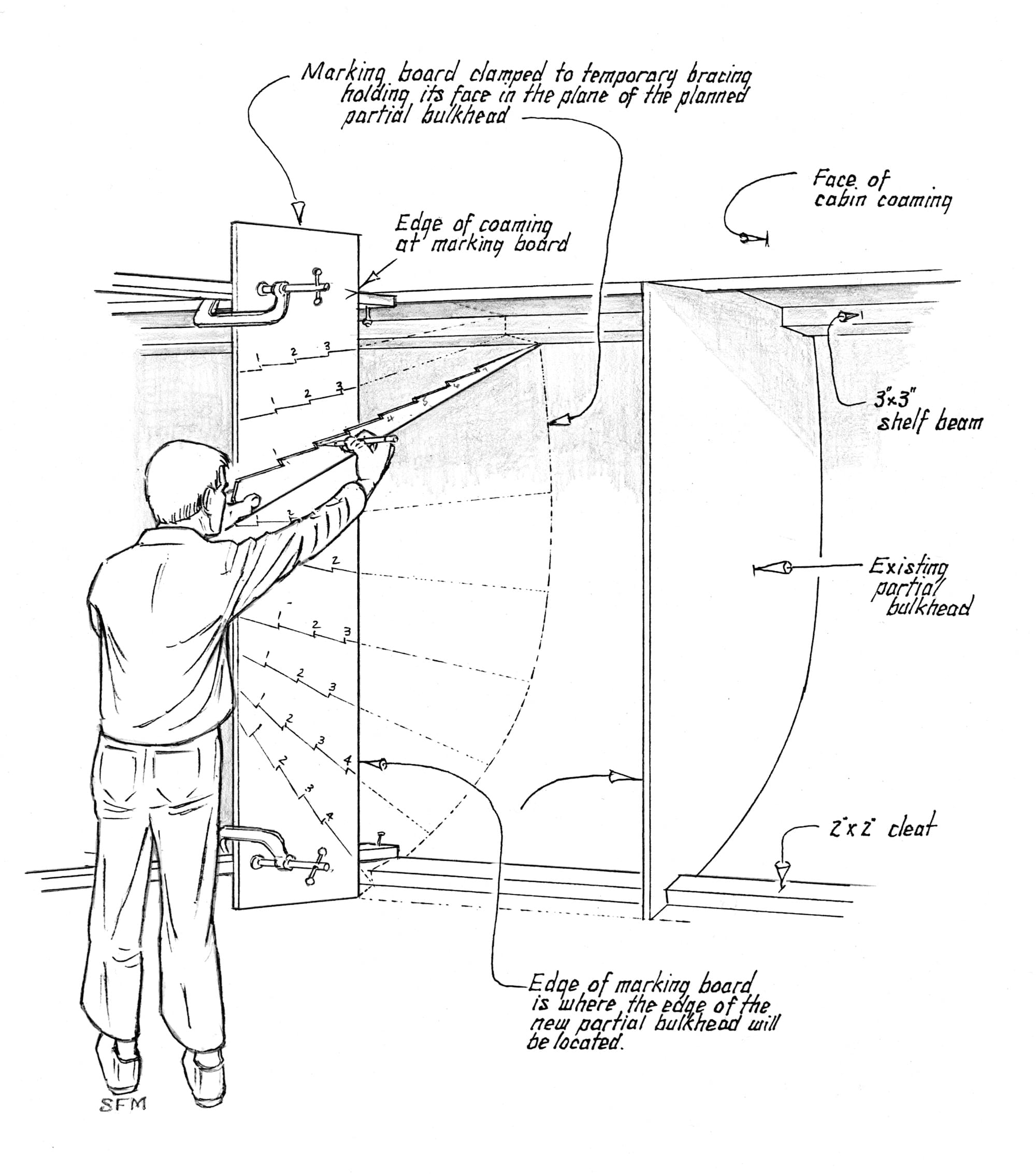

When making a pattern for a bulkhead where you have to deal with curved surfaces, things can get messy, especially if you have shelves, cleats, and stringers in the way. Here’s where the joggle stick comes into its own. Use it with a marking board to pick up a series of points that define the bulkhead edge, then use it again to transfer the information from the marking board to the bulkhead stock. Once you try the joggle stick, you’ll never use anything else for fitting complex shapes and curves. This elegantly simple device, which, I’m told, dates back to 19th-century British shipwrights, is as useful today as when it was invented.

Making the Joggle Stick

Make the joggle stick from a piece of thin wood. I find 1⁄4"-thick birch plywood a good choice for the joggle stick that serves my current project: fitting a 1⁄2" thick, partial bulkhead. For a much shorter version, thinner stock is preferable; conversely, for an extra-long joggle stick, thicker stock is best. Other materials, such as hardwood and plastic, will work well, too. As long as the material is straight, stiff, and able to be cut so that clean marks may be made against it, it is suitable.