You may find it hard to believe that there are hundreds of ways to make and hang a rudder, and about as many ways it can go wrong-to bind, or break, or jam, or fall off, or twist the stern of the boat out of shape. In some ways, the rudder is the most complicated and important part of your new vessel. I’ll attempt to describe, with the help of Sam’s drawings, how I have made and installed just two types of rudder, as I have done them dozens of times. (I’ll skip the pop-ups, the balanced spades, the Viking steering-oars, the aimable jets-all of which simply move the stern of the boat sideways, and aim the bow where you want it to go.)

The first type, then, is the classic inboard rudder. It is hung on the stern post, usually with a jog in its forward edge to make room for a propeller; the stock enters the counter through a watertight tube and stuffing box. It is controlled by tiller, or quadrant with cables, or one of the various worm-gear, rack-and-pinion, or hydraulic push-and-pull mechanisms. In olden times (before I started making rudders, that is), this stock might have been made of wood, an upward continuation of the rudder’s leading edge, housed and turning in a planked-up rudder trunk or port. I have rebuilt such an installation in elderly Friendship sloops and catboats (and have listened to bitter complaints about how the damned ports always leaked), but I am happy that we later builders, with access to better and cheaper metal, have managed to do a neater and possibly more reliable job in our little boats. Bear with me, then, while I try to describe my way of building, hanging, and controlling this inboard rudder.

Shaping the rudder stock (inboard)

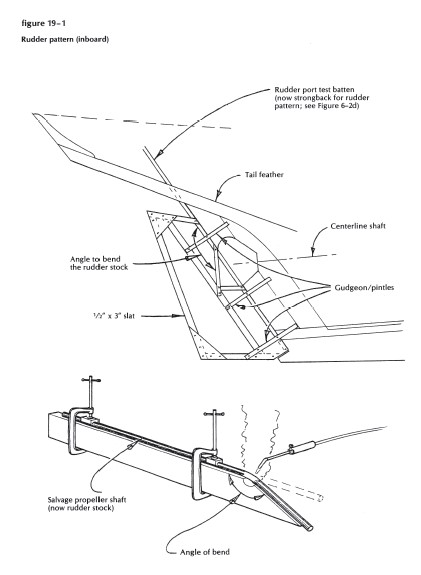

I usually start operations by making a skeleton pattern, showing the location and angle of the propeller shaft, the propeller aperture, the exact angle of the jog in the stock, and the locations of the pintles. All this information is marked on or tacked to a straight lath that represents the forward edge of the rudder-to-be (see Figure 19-1).

The first and apparently most formidable job is to shape that stock-either by making a pattern, and casting it in bronze (as we’ve done several times, in agony and at vast expense), or by bending a good piece of propeller shaft to the correct angle. The latter is the simple and, if I may say so, the right way to do it. A good bronze propeller shaft (we usually managed to find a secondhand one, cheap) is a reliable piece of gear, while a casting is sometimes suspect; I’ve known of a couple of rudder stocks that wrung off at a bad moment.

So-to bend this shaft to the exact angle you clamp it atop something solid, with the short end overhanging the edge of the platform. Arrange a stop to catch the end when it droops to the proper angle, and proceed to heat it at the bending point with a big, blue flame from your borrowed torch. Mind not the color of the heat, nor grow impatient and doubting. Maybe apply a very light pressure out on the end, and wait until it droops gently of its own sweet will, and stops just where you planned. Leave it to cool. Drill it precisely fore-and-aft for the ½-inch bolts. (This is best done on a drill press, of course, and the holes will require some tapered reaming and countersinking to take the forged heads of the bolts.) You will rejoice at the thought that the dogleg in this rudder stock handles the main part of the turning load, and the bolts are thus relieved of a great deal of stress.

The blade itself

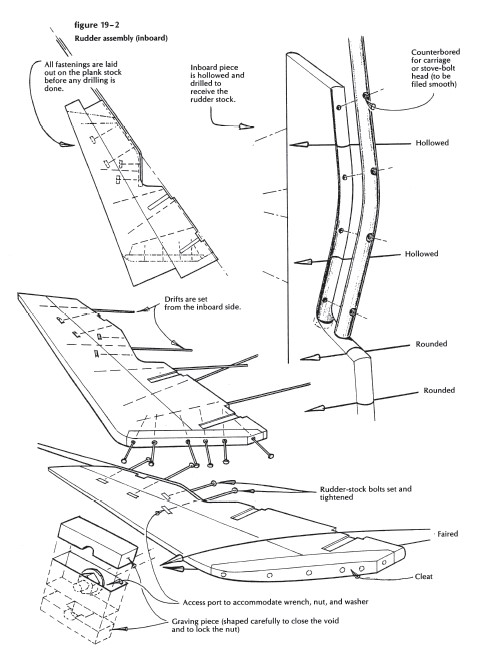

So now we need a blade to wave behind this stock. I have always shaped this of wood, usually in two pieces-the main part fitted precisely to the bronze stock, and the after piece drifted to it, tapering to a fine edge aft. That’s a simple proposition, but some care is needed in the selection and shaping of that wood. If you have had to cope with a few warped rudders, you’ll understand the problem-which arises from wood’s tendency to change shape with every change in moisture content. It is therefore reasonable to suggest that the wood, when shaped, should be as wet as wet can be, because that’s how Old Ocean will keep it. You don’t want something “perfectly seasoned”; you want, if possible, a .. piece from the middle of the log, with the annual rings square across it. You may also want to install a cleat on the bottom-and two sets of flat bronze bands, through-riveted, if all else fails. You must, of course, groove the rudder’s forward edge to accept almost half the diameter of the stock in a light-tight fit, and then drill dead-center for the bolts.

(It might be worthwhile at this point to consider what happens if this rudder can be made without the bend in the stock-for a boat with an off-center propeller, Herreshoff style, or for no propeller at all. This pleasant state would seem to allow a simpler, more efficient rudder; but its strength would depend almost entirely on the edge-bolts’ resistance to bending, without the great power of that crooked stock to apply pressure to the blade.)

Hanging the rudder (inboard)

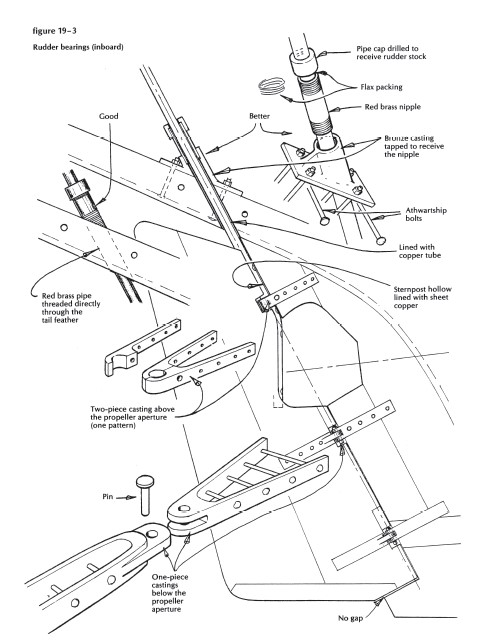

Let’s assume that you’ve bolted the main (forward) piece of the rudder blade to the stock, as in Figure 19-2, and are ready to hang (or hinge) this rudder in place. I like to support it on four bearings: a stuffing-box of some sort on top of the tail feather, one bearing above the propeller aperture, and two more below it with the bottom bearing as low as possible. To you who have gazed long at modern. spade rudders, this may seem a needless excess of good bronze castings; but I will not begrudge the extra cost. Look at Figure 19-3, and prepare to make the patterns.

The bearing above the propeller aperture must fit, of course, around the main stock, and must be such that you can install it with the rudder in place-and, incidentally, remove it with no great trouble in case of damage. The great Nat Herreshoff used a two-piece fitting, riveted together and to the sternpost. I have meekly and thankfully used the same device since I first encountered it on a Herreshoff boat, and have not known it to fail or even wear to a sloppy fit. One pattern, of course, will do the two halves. Use 3/8-inch hardened copper rivets through the stern post, with perhaps a ½-inchbronze rivet where the two halves come together.

And as for the bearings below the propeller aperture: I use one-piece castings, as shown, on the sternpost, with long straps let in flush and through-riveted. The mating half, on the rudder, slides in and is secured by the floating pin. (I assume that you can handle the simple patternmaking involved, and I hope that your foundry will pour good, old reliable naval bronze, which will bend, and stretch, and hang in there long after the supermetals have perished from an excess of strength.)

Let’s go clear to the top, now, and arrange for the stock to lodge inside the boat. This requires a hole through the tail feather that is aimed exactly down the line of the sternpost, and had best be lined with everlasting metal to keep the worms out. (They love dark, unpainted rudder-stock holes.) We usually achieved this ideal by boring for a threaded-pipe rudder port, of best red brass, screwed down through the timber. The right clearance for our standard ½-inch-diameter rudder stock was provided by 1 ½-inch I.D. pipe, and a pipe cap, drilled out to shaft size, served to jam flax packing around the top of the stock to keep the port watertight. This installation required some precise work-boring a hole exactly in line, of correct diameter to take the thread on the pipe for a perfect fit, tight enough to allow no working or leakage. (We put bolts horizontally through the timber, above the planking both forward and aft of the port, to guard against any split that might develop.) We used this simple system on dozens of boats, with the approval of the designers and our own consciences, and with no catastrophic failures, but we finally chose a more complicated arrangement-a custom-made casting to fit each particular boat, which was better in several ways. As shown in Figure 19-3, this is a heavy casting, with a wide base, angled to bolt on top of the tail feather, and fitted with a packing gland. This casting provides a stronger support for the rudder stock, and can always be re-seated if any leak develops under its flanged base. (It’s a very pretty piece of patternmaking, too, and fine practice for the work you’ll be doing someday on goosenecks and hawsepipes.)

You’ll core for the hole, and clean the casting itself out to a smooth clearance for the rudder stock; and you’ll wait, for the final fitting and bolting, until you’ve swung the rudder into place (having, of course, lined the rudder port with copper tube or lead sleeve, and the grooved sternpost with sheet copper.) Drop the lovely casting down over the stock, shave the top of the horn timber ( tail feather) to correct for any tiny errors in angle, and fasten it down-preferably with naval bronze bolts, to match the metal in the casting. And I mean bolts, four of them, all the way through the tail feather. Bronze screws are not good enough. I’ve seen one of these castings, screw-fastened, all adrift and leaking torrents, and the boat was only 40 years old.

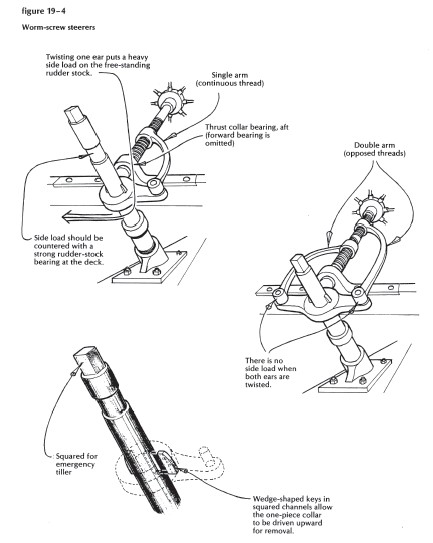

Two more warnings. First, the heel of the rudder must sit tightly upon an extension of the . deadwood, or in some sort of heel bearing, with no gap to catch your overridden anchorline or a lobster-pot warp. Second, the stock should, if possible, extend upward through a strong bearing at the deck, with an exposed fitting to take an emergency tiller. This upper bearing helps to withstand the severe side-load generated by the lever arm of the steering device working against the pressure of the rudder-and note that the load approaches infinity as the tiller length approaches zero. This sounds like a desperate way to describe the situation. Your knowledgeable friends will point out, patiently, that the torque on the rudder head remains constant, whatever the length of the lever arm, and that a hydraulic ram with a 100-pound thrust against a I-inch tiller has the same turning effect (torque) as a 1-pound thrust on a 100-inch tiller-or words to that effect. But these experts always ignore the side-thrust, which is the cause of much rudder trouble. Therefore, if you choose a worm-screw steerer (and a very good choice it is, if you can find one), get the double-arm style, as shown in Figure 19-4. If you can grab the brat by both ears, you can twist its neck without breaking it off. That hydraulic ram looks like a perfect solution, but its power must be countered by strong bearings, above and below, or it can wring the stern right off.

An outboard rudder

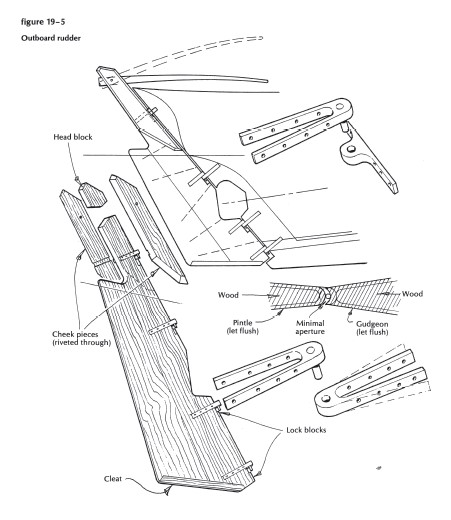

I trust that the above has put you in a proper frame of mind to appreciate the other kind of rudder-hung outdoors for all to see, vulnerable to attack by pirates, and terminating the length of the vessel in a no-nonsense lack of overhang. There are some (myself among them) who feel that after overhang in a vessel is worth its cost and weight when that vessel is running downwind in a big following sea; but that is a matter of opinion only, and fares poorly against the obvious and numerous virtues of the sawnoff stern and its outboard rudder: No holes through the hull; a cinch for a self-steering setup; cheap, strong, all-wood construction. Beauty is, after all, in the eye of the beholder, and most of the present-day beholders are too young to have been corrupted by the seductions of ancient classics; so let’s get at it, and build an outboard rudder. (See Figure 19-5.)

Begin with the technique as described for the inboard rudder, first making a skeleton pattern from a thin board for the main piece, marked with the line of shaft, the propeller aperture, the top of the transom, the location of the pintles, the angle of the bottom in profile. Now find the best piece of oak that ever grew on the cold hillside-a plank sawn from near the center of the butt log, blue in color, with interlocked grain and a tough, mean look about it. Joint one edge of this plank absolutely straight, and lay it in, waiting until you’ve installed the gudgeons on the transom and the sternpost.

Hanging the rudder (outboard)

It’s unlikely that you can locate off-the-shelf hardware for hanging this rudder, so you’ll do well to make patterns and get castings before proceeding any further. Note that the gudgeon on the stern post are one-piece castings, and that one pattern will do for all three-the upper one, shorter in the arms and wider in the spread, can be bent wider and sawn shorter. (If the bronze won’t stand that much bend, you’d better take the whole batch back to the foundry, and demand something better. Your rudder hardware must be above reproach.)

The fitting high on the transom must obviously have a flat base, to take bolts fore-and-aft through the transom knee; the other three are let into the stern post, above and below the propeller aperture and at the lower end of the post, and riveted through with 3/8-inch copper. And bear in mind, while you are fitting these, that one slight misalignment will lead to strained fastenings, worn bearings, noise, and the expenditure of about 50,000 unnecessary footpounds of energy over the next 30 years. So take care, and get them in line. Install the top and bottom gudgeons, and align the others to a tight string between centers; or, easiest of all, use a length of cold-rolled steel shaft (borrowed, of course, and perfectly straight) to work to, for the final, delicate fitting.

All you need to do now is line up and rivet the pintles on the rudder, to match the gudgeon spacing; cut the aperture for the propeller, if any; fit the cheek pieces at the top, to take the tiller; and shape, drill, and drift the second (aft) piece to this main one. Taper this trailing edge of the rudder blade as much as you dare, so that the wake will close in around it, slick as off a mackerel’s tail. (Many years ago I was told, separately and at length, by two of the most revered of all authorities, that this after edge should be left thick and square. One of the sages claimed that those bubbles and swirls were actually pushing the boat ahead; the other maintained that this area of confused currents increased the turning effect of the rudder to the extent of doubling its area. I delved into the theory of perpetual motion to strengthen my distrust of the first sage; and I eventually added another tapered plank to the rudder designed by the second that seemed, somehow, to lack authority in the likelihood of having to coax the vessel onto the other tack. I won’t tell you the names of these two, lest I be scourged to a dungeon by you who worship the True Word. But I advise you to make that blade big enough, and taper it down very thin.)

That cleat on the bottom edge may look somewhat amateurish, but it covers end grain, and helps wonderfully to withstand warping.

The tiller

And now, to control this outboard rudder: the simplest, cheapest, strongest, and most reliable means is a tiller (the longer, the better) that comes inboard above the top of the transom. It need not allow for swinging more than 40 degrees from center amid sheet blocks and gallows frames, and it should fetch up against a positive stop when hard over. You can add controls to it in a dozen different ways-lines on tackles from both sides, with quick-jam locking devices on them; or a notched comb, as in the old lobster sloops; or removable pegs in a crossbar, to stop the swing (and never in exactly the right place)-and even that wonderful system, unbelievable, called the Shin Cracker (described by Frank Bullen in Cruise of the Cachalot, incidentally) which mounted a steering wheel, with drum, on the end of the tiller, and wound itself back and forth across the deck like a spider trying to make up its mind. The helmsman got a peek at the compass whenever his travels brought him past it. (Bullen’s initial horror, I’m happy to state, softened to a grudging admiration for the system before the cruise was long underway.)

Let’s suppose, now, that your design (or desire) calls for conventional wheel steering, with stub tiller or quadrant entering through, rather than over, the transom. A quadrant, whether grooved for cable or toothed for gear, will fetch up against the inside of the transom when hard over, and make you wish it would go another 10 degrees. A straight tiller (plenty long, to keep low the strains on cable and rudderhead) can be arranged to give you an easy 40 degrees or more, and still fetch up against a positive stop clear of the transom; but you will have to accept uneven tension on the cables as the tiller goes from center to hard over. This effect is not as bad as it may sound; we’ve done dozens of rigs like this over the years, and they all worked. Inevitably, cables wore out and broke, and we learned the hard way that the finest stainless steel is the least durable material for steering cables. Plain steel, well greased, seems to last twice as long. Bronze tiller rope, if you can find it, is better yet-and then, there’s thain, and hard-laid Dacron. Design the parts of this system to give you at least three revolutions of the wheel from hard over to hard over, and be sure that you’ve provided for quick attachment of your emergency tiller, and have done something to bar insects and wavetops from entering your vessel through that tiller slot. We have used a rubber tube, seized around the inner neck of the tiller, and fastened tight to the circumference of the transom opening. An inner tube out of a truck tire (if there is yet such a thing available) does very nicely, and endures the flexing for a long time.

And, finally, this warning: Ignore the advice of those who tell you to install all these sheaves, cables, and push-rods while they are easy to get at, with no deck and cockpit in the ‘Vay. That is bad thinking. Some distant day, a sheave will freeze, or a cable break, or a key wiggle loose, and you’ll have to crawl in and repair the damage, before you get blown onto a lee shore. When that day comes, you’ll be glad you planned and installed these parts, originally, with everything in the way. If you did it once, you can do it again; but if you did it the sensible way, with the hull wide open, and then buried your steering installation behind handy shelves and impregnable bulkheads, you’ll be sorry indeed. In the meantime, plan everything so that it can’t possibly break, or corrode, or jam. Grease those sheaves, check the cables, and be sure the ash tiller hasn’t rotted at the rudderhead. Should have been black locust, anyway. Happy steering to you.