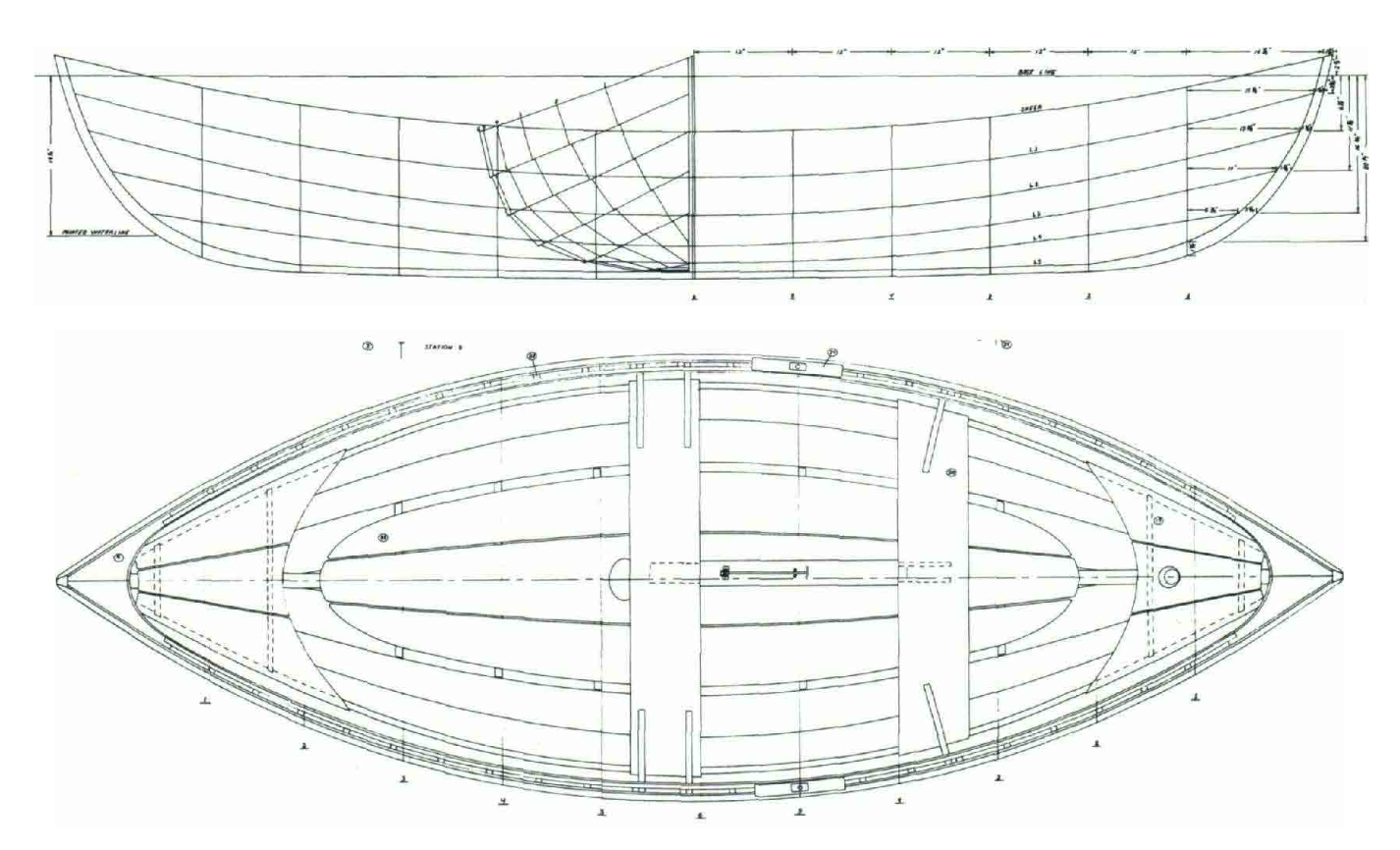

In Building the Beach Pea, Part 1, we described the preliminary steps of the project, including preparing the shop, gathering the tools and building materials, making the ladderframe, scarfing the plywood panels and laminating the stems. Now, we're ready to build the hull of the boat.

Making the Molds

Being somewhat of a cheeseparer, I can't bring myself to spend a lot of money on parts that don't wind up in the boat. The molds fall into this category, and my current favorite material for making them is " or ¾" particle board. This stuff is really cheap and, if kept dry, is reasonably stable and stays flat. It's durable enough to be used for one or two boats before the edges start to fall apart. Cheap plywood tends to bow and twist, making it difficult to keep square and plumb on the setup. An astute observer will notice that the molds in the photos are made of solid stock. This was done because we planned to build several boats from these molds, and solid wood will stand up to long use and storage in damp conditions. But for most of you, particle board will be much cheaper, faster, and just as serviceable.